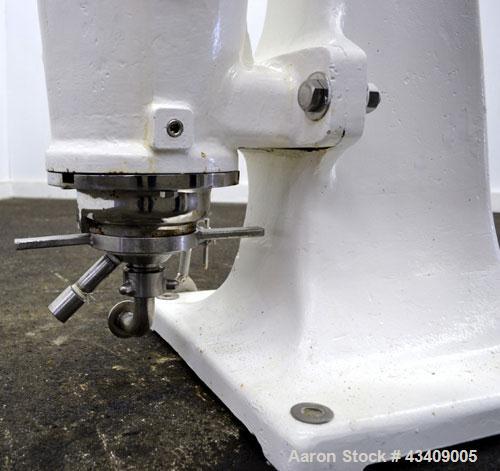

Sharples-centrifuge-manual 1/2 Downloaded from liceolefilandiere.it on December 22, 2020 by guest eBooks Sharples Centrifuge Manual Yeah, reviewing a books sharples centrifuge manual could ensue your close links listings. This is just one of the solutions for you to be successful. As understood, feat does not recommend that you have wonderful. Sharples Manual - PDF Manuals Library Sharples Centrifuge Manual compiled pdf, doc, ppt - sharples centrifuge manual - Fast Download: 7.76 MB: 9: 486: emanjamshidi Alfa Laval, Sharples P880, P1500 New, Unused Super D-Canter Centrifuge: 3.75 MB: 9: 107 sharples decanter centrifuge manual - free pdf - sharples decanter centrifuge. The Super centrifuge is a vertical high speed tubular bowl centrifuge, generating centrifugal force up to 20000 times the force of gravity. It is used either for continuous separation of two immiscible liquids having different specific gravities or for batch-wise clarification. Used AS26SP Sharples Super centrifuge, 316 stainless steel construction, 17000 RPM bowl speed, heating/cooling coils, triple mechanical seal for sterilizatoin to 255 degrees F @ 22 PSI, 1.1 specific gravity rating, 8.6 liter bowl capacity, 6.5 liter solids holding capacity, centripetal pump liquid discharge, with 5 HP 230/460 volt XP motor.

2020-11-10 14:59:36

2020-11-10 14:58:41

2020-11-10 13:44:39

2020-10-16 16:21:50

2020-10-09 19:47:08

Surplus centrifuges manufactured by Evodos, Alfa Laval and GEA Westfalia available for harvesting of micro algae. Quick delivery and low prices when compared to new centrifuges.

Decanter and disk-stack centrifuges are used for separation of fine solids (yeast, pulp, grain, etc.) from beer, wine and fruit juices as part of the production process. Eliminates or reduces the need for filters and their recurring costs.

Kyte Centrifuge offers reconditioned centrifuges for biodiesel applications. Our centrifuges are suitable for instantaneous and continuous separations in the biodiesel process. Centrifuges supplied by Kyte Centrifuge are currently being used for: Pre-treatment of Feedstock including: Separation of gums (degumming), solids, water, and soap stock from un-refined vegetable oils, yellow grease, brown grease (trap grease), waste vegetable […]

Decanter centrifuges are used for separation of solids from weighted and unweighted drilling muds, barite recovery, and separation of oil based drilling mud from cuttings. Solids control is crucial to maintaining proper mud characteristics including extending the life of the drill bit. New and reconditioned centrifuges are available with quick delivery. We can offer decanters which […]

Sharples As16 Centrifuge Manual Download

Decanter centrifuges are used for continuous dewatering of spent grain and cellulosic ethanol slurries post-fermentation. Decanter centrifuges offer a high degree of dry cake solids with low energy consumption when compared to other drying technologies. This increases value as an animal feed. Reduced solids in the fermentation liquid enable higher concentrations to be produced by […]

Decanter, solid bowl basket, and disk-stack centrifuges are used for separation of water and solids from industrial machining coolants as well as fuel, turbine and lube oils. Both solids-retaining and self-cleaning disk stack models are available. Sizes range from 1 – 300 GPM. Purified coolants and lube oils can be recycled thereby reducing your plant’s […]

Sharples As16 Centrifuge Manual Free

Hydrovac or Hydro Excavation waste water or mud, is the result of injecting pressurized water into the ground through a hose; liquefying the soil into a slurry mix. The wet soil or “mud slurry” is then sucked up using a high capacity vacuum pumping system and stored in a truck. The resulting hydro waste slurry must be […]

Dewatering of flushed dairy, swine, cattle, poultry or other animal manure waste, older lagoons sludges, or to dewater aerobic or anaerobic digester sludge. Eliminates thousands of gallons of water applied to the fields. The manure separator solids dry cake at up to 31% dry material can still be aplied to the fields, if desired, without […]

Decanter and disk stack centrifuges are used for separation of water and solids from rendered fats, blood, grease, and oil in both edible and in-edible rendering. Also used for fat, oil and grease (F.O.G.) recovery from a DAF wastewater system.

Kyte Centrifuge now offers reconditioned and new centrifuges engineered for solvent extraction of CBD (cannabidiol) oil from hemp. We also offer centrifuges for separation of CBD isolate as part of the production process. Special design considerations must be made when using centrifuges in Class 1 Div. 1 explosion-proof and vapor tight design requirements. Our company […]

Decanter and disk-stack centrifuges are used for separation of solids and water from trap greases (brown grease, yellow grease, etc.) Separation of minor oil & water emulsions is possible. No filter media, screens or clothes used. No full time operator required. Reduces polymer & lime consumption as part of the water treatment process, thereby reducing […]

Decanter and disk-stack centrifuges are used routinely in the vegetable oil refining process, whether it is for use in biodiesel or food production. Applications include: Clarification of press oil. Continuous separation of meal solids, foots, and gums. Water Degumming. Separation of hydratable gums (phosphalipids) and other solubles. Acid Degumming. Separation on non-water soluble gums Neutralization […]

Decanter, solid bowl basket and disk-stack centrifuges are used to clarify, classify, thicken, dewater many waste sludges including those generated by the industrial, water treatment and municipal sewage treatment markets.

Consignment services are available for your idle surplus equipment. If you have a piece of equipment that you would like for us to inventory and advertise to our customer base, please fill out the information below and someone will contact you with details about our program.

Consulting services offered include: Start up Assistance Process Optimization Operator Training Testing Trouble-shooting Expert Witness Please contact us for rates and availability.

Kyte Centrifuge offers NEW modern control systems using PLC and VFD technology. New control systems are easily retro-fitted to an existing centrifuge in your plant regardless of the equipment’s age. Customized programming of the PLC is tailored to meet your process and clean-in-place requirements. All control systems are offered with a one-year warranty. Start up assistance and training […]

Kyte Centrifuge wants your surplus – used centrifuges! We purchase surplus – used centrifuges. Machines we are unable to purchase can be offered in a consignment listing where they will be advertised to our broad customer base world-wide. Please contact us regarding your surplus.

Reconditioning services are available for all used centrifuges with new controls and motors offered. Fast deliveries are possible when compared to new equipment. All reconditioned centrifuges come with a limited warranty covering parts and labor.

Complete centrifuge repair and parts service is offered through our affiliated repair centers worldwide.

Kyte Centrifuge offers sales of new, reconditioned, and used centrifuges to meet your requirements.

The Super centrifuge is a vertical high speed tubular bowl centrifuge, generating centrifugal force up to 20000 times the force of gravity. It is used either for continuous separation of two immiscible liquids having different specific gravities or for batch-wise clarification / polishing of liquids containing fine insoluble solids.

Pennwalt Ltd. are manufacturers of high-G Tubular bowl Centrifuges model AS12, AS16 and AS26 based on the technology acquired from Sharples Stokes Division Pennwalt Corporation-USA.

Pennwalt also supply spare parts manufactured to international standards that are interchangeable on each of the above models of the high-G Tubular Bowl Super Centrifuge

This sectional view of a Super-Centrifuge shows the application of centrifugal force to a mixture of two immiscible liquids containing some suspended solids.

The mixture continuously enters the Super-Centrifuge through an inlet feed nozzle at the base of the machine, into the hollow cylindrical rotor. Rotors have been designed and engineered to rotate at 17000 r.p.m. and generate centrifugal force of upto 20000 times the force of gravity.

This force separates the two liquids according to their specific gravities into concentric cylindrical layers, and the solids are deposited inside the rotating bowl against the rotor wall.

The separated liquids are continuously displaced upwards by the incoming mixture and continuously discharged through their respective outlet ports at the top of the rotor. The layer of accumulated solids that builds up on the inner diameter of the rotor wall is cleaned out batch-wise for which the super-centrifuge is shut down when it is filled up to the rotating bowl’s limiting solids holding capacity and the rotating bowl is removed for cleaning.

There are, however, many applications where only the removal of suspended solids from a single liquid is required. Super centrifuges for such applications are called Clarifiers and are often provided with only one set of discharge ports. Mylar Liners are optionally supplied and can be placed on the inner diameter of the bowl for ease of removal of insoluble solids deposited on the inner diameter of the bowl